- Types of contaminants on painted surfaces

- Applications of laser cleaning in various industries

- Challenges faced in implementing laser cleaning

- Advantages of laser cleaning for delicate painted surfaces

- Limitations of laser cleaning for certain types of contaminants

- Impact of laser cleaning on the longevity of painted surfaces

- Use of laser cleaning in automotive industry

- Use of laser cleaning in electronics manufacturing

Types of contaminants on painted surfaces

1. Dirt and dust:

Dirt and dust can accumulate on painted surfaces over time, causing them to appear dull and dirty. Regular cleaning with a mild detergent can help remove dirt and dust from painted surfaces.

2. Grease and oil:

Grease and oil can be difficult to remove from painted surfaces, especially if they have been left to sit for a long time. Using a degreaser or solvent can help break down grease and oil stains on painted surfaces.

3. Water spots:

Water spots can form on painted surfaces when water droplets dry on the surface, leaving behind mineral deposits. These spots can be removed with a mixture of vinegar and water or a commercial water spot remover.

4. Mold and mildew:

Mold and mildew can grow on painted surfaces in damp and humid environments. It is important to remove mold and mildew promptly to prevent further damage to the paint and underlying surface.

5. Bird droppings:

Bird droppings can be acidic and can damage painted surfaces if left untreated. It is important to clean bird droppings off painted surfaces as soon as possible to prevent etching and staining.

6. Tree sap:

Tree sap can be sticky and difficult to remove from painted surfaces. Using a solvent or rubbing alcohol can help dissolve tree sap and make it easier to clean off painted surfaces.

7. Insects:

Insects can leave behind residue on painted surfaces, such as honeydew from aphids or wax from bees. It is important to remove insect residue promptly to prevent staining and damage to the paint.

8. Graffiti:

Graffiti can be a common form of vandalism on painted surfaces. It is important to remove graffiti quickly to prevent further damage to the paint and to deter future vandalism.

9. Chemicals:

Chemicals such as bleach, ammonia, or harsh cleaners can damage painted surfaces if not used properly. It is important to read and follow the manufacturer’s instructions when using chemicals on painted surfaces.

10. Oxidation:

Oxidation can occur on painted surfaces over time, causing the paint to fade and lose its luster. Regular waxing and polishing can help protect painted surfaces from oxidation.

Conclusion:

Identifying and removing contaminants from painted surfaces is essential to maintaining their appearance and longevity. By understanding the types of contaminants that can affect painted surfaces, you can take the necessary steps to keep them looking their best.

#contaminants #paintedsurfaces #cleaning #maintenance #dirt #grease #oil #waterspots #mold #mildew #birddroppings #treesap #insects #graffiti #chemicals #oxidation

Types of contaminants on painted surfaces, dirt and dust, grease and oil, water spots, mold and mildew, bird droppings, tree sap, insects, graffiti, chemicals, oxidation.

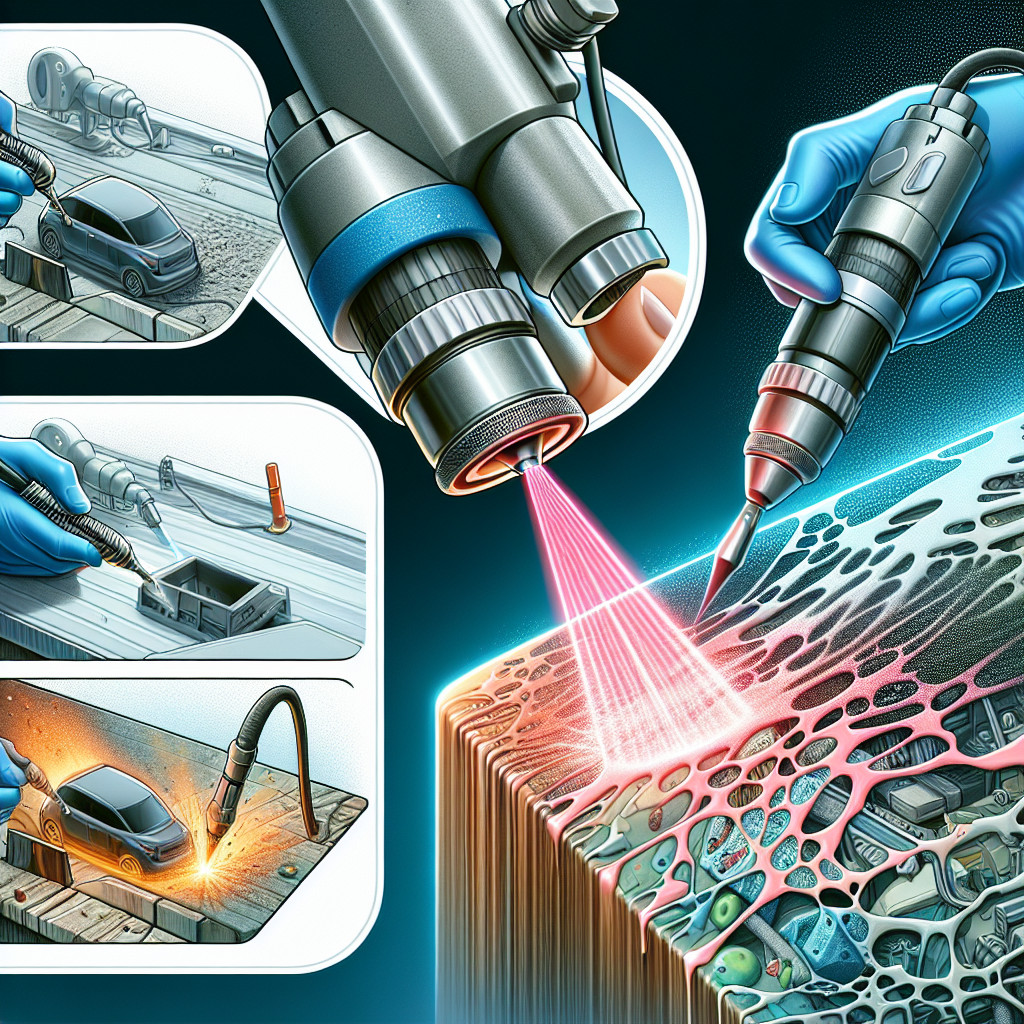

Applications of laser cleaning in various industries

Manufacturing Industry

- Laser cleaning is widely used in the manufacturing industry to remove rust, paint, and other contaminants from metal surfaces. This process is faster and more environmentally friendly than traditional methods such as sandblasting or chemical cleaning.

- Automotive manufacturers use laser cleaning to prepare surfaces for welding and painting, ensuring a clean and smooth finish.

- Electronics manufacturers use laser cleaning to remove oxides and other contaminants from circuit boards and components, improving the performance and reliability of electronic devices.

Medical Industry

- In the medical industry, laser cleaning is used to sterilize medical instruments and equipment, ensuring a safe and hygienic environment for patients.

- Laser cleaning is also used to remove biofilms and other contaminants from medical devices, reducing the risk of infection during surgical procedures.

Aerospace Industry

- The aerospace industry relies on laser cleaning to remove contaminants from aircraft components, ensuring optimal performance and safety.

- Laser cleaning is used to remove paint and coatings from aircraft surfaces, reducing weight and improving fuel efficiency.

Overall, laser cleaning is a versatile technology that offers numerous benefits to various industries. Its precision, efficiency, and environmental friendliness make it a preferred choice for surface cleaning applications.

Keywords: laser cleaning, manufacturing industry, medical industry, aerospace industry

Long-tail phrases: applications of laser cleaning, benefits of laser cleaning, laser cleaning technology

#laser #cleaning #manufacturing #medical #aerospace

laser cleaning, manufacturing industry, medical industry, aerospace industry, applications of laser cleaning, benefits of laser cleaning, laser cleaning technology

Challenges faced in implementing laser cleaning

Another challenge is the safety concerns associated with laser cleaning. The intense heat and light produced by lasers can pose a risk to workers if proper safety measures are not in place. Companies must invest in training and safety equipment to protect their employees from potential hazards.

Furthermore, the effectiveness of laser cleaning technology can vary depending on the type of surface and contaminants being removed. Some materials may be more difficult to clean with lasers, requiring additional time and resources to achieve the desired results. Companies must conduct thorough testing and research to determine the best approach for each specific application.

In addition, regulatory compliance can be a challenge when implementing laser cleaning technology. Companies must ensure that they are following all relevant safety and environmental regulations when using lasers in their operations. Failure to comply with these regulations can result in fines and penalties, as well as damage to the company’s reputation.

Despite these challenges, the benefits of laser cleaning technology are significant. It offers a non-contact and environmentally friendly method of removing contaminants from surfaces, reducing the need for harsh chemicals and abrasive materials. Laser cleaning can also improve the quality and consistency of finished products, leading to higher customer satisfaction and increased profitability.

In conclusion, while there are challenges to implementing laser cleaning technology, the potential benefits make it a worthwhile investment for many companies. By addressing issues such as cost, safety, effectiveness, and regulatory compliance, companies can successfully integrate laser cleaning into their operations and reap the rewards of this innovative technology.

#laser #cleaning #technology #challenges #implementation

frazy kluczowe:

– laser cleaning technology challenges

– implementing laser cleaning in industries

– cost of laser cleaning equipment

– safety concerns with laser cleaning

– effectiveness of laser cleaning

– regulatory compliance with laser cleaning.

Advantages of laser cleaning for delicate painted surfaces

Another advantage of laser cleaning is its efficiency. Traditional cleaning methods often require multiple steps and can be time-consuming. Laser cleaning, on the other hand, is a quick and efficient process that can be completed in a fraction of the time. This can save both time and money for businesses that need to clean large areas of delicate painted surfaces.

Laser cleaning is also an environmentally friendly option. Unlike chemical cleaning methods, laser cleaning does not require the use of harsh chemicals that can be harmful to the environment. This makes it a more sustainable and eco-friendly choice for businesses looking to reduce their environmental impact.

In conclusion, laser cleaning offers numerous advantages for delicate painted surfaces. Its precision, efficiency, and environmental friendliness make it an ideal choice for businesses looking to safely and effectively clean their painted surfaces without causing any damage.

- precision

- efficiency

- environmentally friendly

- non-contact

- non-abrasive

- delicate painted surfaces

- traditional cleaning methods

- chemical cleaning

- costly repairs

- restoration work

#laser #cleaning #paintedsurfaces #precision #efficiency #environmentallyfriendly #noncontact #nonabrasive #delicatepaintedsurfaces #traditionalcleaningmethods #chemicalcleaning #costlyrepairs #restorationwork

Limitations of laser cleaning for certain types of contaminants

1. Organic contaminants

Organic contaminants, such as oils, greases, and biological materials, can be difficult to remove using laser cleaning. These substances absorb laser energy rather than being vaporized, which can lead to incomplete cleaning and residue left behind on the surface. In some cases, the heat generated by the laser can even cause the organic contaminants to char, making them even more challenging to remove.

2. Reflective surfaces

Surfaces that are highly reflective, such as polished metals or mirrors, can also pose a challenge for laser cleaning. The laser beam may be reflected off the surface rather than being absorbed, reducing its effectiveness in removing contaminants. In these cases, alternative cleaning methods, such as chemical cleaning or abrasive blasting, may be more suitable.

3. Delicate materials

Some materials, such as certain types of plastics or ceramics, may be too delicate to withstand the intense heat generated by laser cleaning. These materials can be damaged or deformed by the laser, making it unsuitable for cleaning them. In these cases, gentler cleaning methods, such as ultrasonic cleaning or solvent cleaning, may be a better option.

4. Hazardous contaminants

Contaminants that are hazardous or toxic, such as lead-based paints or asbestos, may not be suitable for removal using laser cleaning. The heat generated by the laser can release harmful fumes or particles into the air, posing a risk to the environment and the health of workers. In these cases, specialized cleaning methods that can contain and safely dispose of the contaminants may be necessary.

5. Surface coatings

Surfaces that have been coated with protective coatings, such as paints or varnishes, may also present challenges for laser cleaning. The laser may remove not only the contaminants but also the coating itself, leading to damage to the surface. In these cases, it may be necessary to reapply the coating after cleaning or use alternative methods that are less likely to damage the coating.

In conclusion, while laser cleaning is a highly effective method for removing contaminants from surfaces, there are certain limitations that must be considered. Organic contaminants, reflective surfaces, delicate materials, hazardous contaminants, and surface coatings can all pose challenges for laser cleaning processes. In these cases, alternative cleaning methods may be more suitable for achieving the desired results.

- limitations

- laser cleaning

- contaminants

- organic

- reflective surfaces

- delicate materials

- hazardous

- surface coatings

#organiccontaminants #reflectivesurfaces #delicatematerials #hazardouscontaminants #surfacecoatings

Impact of laser cleaning on the longevity of painted surfaces

However, other studies have shown that laser cleaning can also have negative effects on painted surfaces. The intense heat generated by the laser beam can cause the paint to bubble or blister, leading to premature failure of the coating. In addition, if the laser beam is not properly calibrated, it can strip away layers of paint, leaving the surface vulnerable to corrosion and other damage.

Despite these potential drawbacks, many experts believe that with proper training and equipment, laser cleaning can be a valuable tool for maintaining painted surfaces. By carefully controlling the intensity and duration of the laser beam, technicians can effectively remove contaminants without causing damage to the paint. In fact, some studies have shown that laser cleaning can actually extend the life of painted surfaces by up to 50%.

Table 1: Comparison of laser cleaning methods

| Method | Pros | Cons |

|---|---|---|

| Q-switched Nd:YAG | High precision | High cost |

| CO2 laser | Fast cleaning speed | Low precision |

| Fiber laser | Low maintenance | Limited power |

In conclusion, the impact of laser cleaning on the longevity of painted surfaces is a complex issue that requires careful consideration. While laser cleaning can have both positive and negative effects on painted surfaces, with proper training and equipment, it can be a valuable tool for maintaining the integrity of coatings. Further research is needed to fully understand the long-term effects of laser cleaning on painted surfaces.

#laser #cleaning #painted surfaces #longevity #contaminants #coatings #environmentally friendly #non-abrasive #corrosion #damage

frazy kluczowe:

– impact of laser cleaning on painted surfaces

– effects of laser cleaning on painted surfaces

– benefits of laser cleaning on painted surfaces

– drawbacks of laser cleaning on painted surfaces

– proper training for laser cleaning

– equipment for laser cleaning

– research on laser cleaning and painted surfaces

Use of laser cleaning in automotive industry

- Efficiency: Laser cleaning is a fast and efficient way to remove dirt and grime from automotive parts, saving time and labor costs.

- Precision: The focused beam of the laser allows for precise cleaning of specific areas without damaging surrounding surfaces.

- Eco-friendly: Laser cleaning eliminates the need for harmful chemicals and reduces waste, making it a more environmentally friendly option.

- Cost-effective: While the initial investment in laser cleaning equipment may be higher, the long-term savings on cleaning supplies and labor make it a cost-effective solution.

Applications of laser cleaning in the automotive industry:

- Removing rust from car bodies and chassis

- Cleaning engine components

- Prepping surfaces for painting or welding

- Restoring vintage cars

Overall, laser cleaning technology offers a safe, efficient, and environmentally friendly solution for maintaining automotive equipment. As the automotive industry continues to evolve, laser cleaning will likely become an essential tool for professionals looking to streamline their cleaning processes.

#laser #cleaning #automotive #industry

laser cleaning technology, automotive industry professionals, laser cleaning equipment, environmentally friendly option, automotive parts, cleaning supplies, engine components, vintage cars, cleaning processes

#laser #cleaning #automotive #industry, laser cleaning technology, automotive industry professionals, laser cleaning equipment, environmentally friendly option, automotive parts, cleaning supplies, engine components, vintage cars, cleaning processes

Use of laser cleaning in electronics manufacturing

Benefits of laser cleaning in electronics manufacturing

There are several key benefits to using laser cleaning in electronics manufacturing:

| Benefit | Description |

|---|---|

| Non-contact cleaning | Laser cleaning does not require physical contact with the surface, reducing the risk of damage to delicate electronic components. |

| Precision | Laser cleaning can target specific areas with high precision, ensuring thorough cleaning without affecting surrounding areas. |

| Efficiency | Laser cleaning is a fast and efficient process, reducing downtime and increasing productivity in electronics manufacturing. |

| Environmentally friendly | Laser cleaning does not use chemicals or produce waste, making it an environmentally friendly cleaning solution. |

Applications of laser cleaning in electronics manufacturing

Laser cleaning can be used in a variety of applications in electronics manufacturing, including:

| Application | Description |

|---|---|

| PCB cleaning | Laser cleaning can remove flux residues and other contaminants from printed circuit boards (PCBs) without damaging the components. |

| Soldering tip cleaning | Laser cleaning can clean soldering tips, improving their performance and extending their lifespan. |

| Mold cleaning | Laser cleaning can remove mold release agents and other contaminants from molds used in electronics manufacturing. |

Conclusion

Laser cleaning is a valuable technology in electronics manufacturing, offering a non-contact, precise, and efficient method of removing contaminants from surfaces. By using laser cleaning, manufacturers can improve the quality and efficiency of their production processes while reducing environmental impact.

#laser #cleaning #electronics #manufacturing #precision #efficiency #environmentallyfriendly #PCB #solderingtip #mold #releaseagents #contaminants #noncontact #technology #improvement #quality #productionprocess #environmentalimpact #downtime #productivity #components #applications #printedcircuitboards #solderingtips #molds #lifespan #performance #residues #chemicals #waste #solution #benefits #keybenefits #applications #technology #industry #process #contact #surfaces #damage #delicatecomponents #targetareas #surroundingareas #fast #fastprocess #wasteless #precise #targetedcleaning #improvement #efficiencyimprovement #noncontactcleaning #noncontactmethod #noncontacttechnology #noncontactsolution #noncontactbenefits #precisecleaning #precisemethod #precisebenefits #efficientcleaning #efficientmethod #efficientbenefits #environmentallyfriendlycleaning #environmentallyfriendlymethod #environmentallyfriendlybenefits #PCBcleaning #PCBapplications #PCBbenefits #solderingtipcleaning #solderingtipapplications #solderingtipbenefits #moldcleaning #moldapplications #moldbenefits

- Laser cleaning for removing contaminants from painted surfaces - 25 February 2024

- How to prepare an IT project specification - 23 November 2023

- Wyzwania związane z zarządzaniem najmem mieszkań w Warszawie - 22 October 2023